Service Phone:

+8619870423316

Service Phone:

+8619870423316

Service Phone:+8619870423316

Service Phone:+8619870423316

current location: home > News and information

24-hour phone/WhatsApp:+8619870423316

24-hour phone/WhatsApp:+8619870423316

Tin ore tailings refer to the waste generated during the tin ore beneficiation process. These wastes usually contain a large number of harmful substances, such as heavy metals and Radioactive element, which pose a great threat to the environment and human health. Therefore, the treatment of tin ore tailings is urgent. The selection and use of equipment play a crucial role in the treatment of tin ore tailings. This article will introduce the equipment and operational steps required for the treatment of tin mine tailings.

1、 Tin mine tailings treatment equipment

1. Magnetic separator

A magnetic separator is a device that uses magnetic substances to separate materials. In the treatment of tin ore tailings, magnetic separators are mainly used to separate iron bearing minerals and non iron minerals. The working principle of a magnetic separator is to use magnetic substances to separate materials, adsorbing iron containing minerals onto magnetic substances, thereby achieving separation.

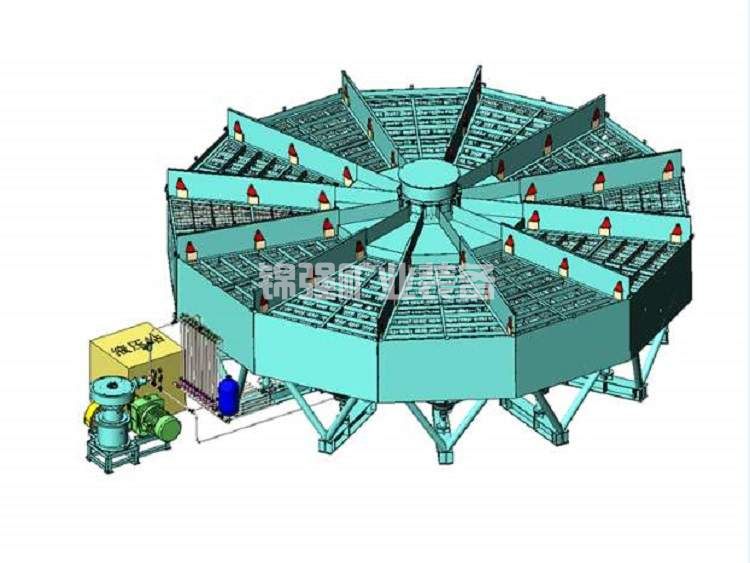

2. Flotation machine

2. Flotation machine

flotation machine is a kind of equipment that uses the density difference of materials for separation. In the treatment of tin ore tailings, flotation machines are mainly used to separate tin containing minerals and non tin minerals. The working principle of the flotation machine is to use the density difference of materials to separate and float the tin bearing minerals to achieve separation.

flotation machine is a kind of equipment that uses the density difference of materials for separation. In the treatment of tin ore tailings, flotation machines are mainly used to separate tin containing minerals and non tin minerals. The working principle of the flotation machine is to use the density difference of materials to separate and float the tin bearing minerals to achieve separation.

3. Screening machine

A screening machine is a device that uses a sieve to separate materials. In the treatment of tin ore tailings, screening machines are mainly used to separate materials with different particle sizes. The working principle of a screening machine is to use a sieve to separate materials of different particle sizes, thereby achieving separation.

2、 Operating Steps for Tin Mine Tailings Treatment

1. Magnetic separation

Firstly, the tin ore tailings are processed by crushing, grinding, and other processes before being sent to a magnetic separator for separation. In a magnetic separator, magnetic substances are used to separate materials, adsorbing iron containing minerals onto magnetic substances, thereby achieving separation. The separated iron containing minerals can be used to produce iron ore concentrates, while non iron minerals are processed in the next step of the process.

2. Flotation

Send the non ferrous minerals after magnetic separation into a flotation machine for separation. In the flotation machine, the density difference of materials is used for separation to float the tin bearing minerals to achieve separation. The tin containing minerals after flotation can be used to produce tin ore concentrates, while non tin minerals are processed in the next step of the process.

3. Screening

Send the non tin minerals that have undergone flotation to a screening machine for separation. In a screening machine, materials are separated using a sieve to separate materials of different particle sizes, thereby achieving separation. The separated materials can be used for production of building materials, landfill cover, etc.

3、 Conclusion

The treatment of tailings from the  tin mine is a very important task, which is of great significance to the environment and human health. The selection and use of equipment play a crucial role in the treatment of tin ore tailings. Magnetic separators, flotation machines, and screening machines are commonly used equipment in the treatment of tin ore tailings, which are used to separate iron and non iron minerals, tin and non tin minerals, and materials with different particle sizes. By treating tin tailings, resource recovery and utilization can be achieved, reducing environmental pollution, and contributing to sustainable development.

tin mine is a very important task, which is of great significance to the environment and human health. The selection and use of equipment play a crucial role in the treatment of tin ore tailings. Magnetic separators, flotation machines, and screening machines are commonly used equipment in the treatment of tin ore tailings, which are used to separate iron and non iron minerals, tin and non tin minerals, and materials with different particle sizes. By treating tin tailings, resource recovery and utilization can be achieved, reducing environmental pollution, and contributing to sustainable development.

Equipment for Tin Mine Tailings

Equipment for Tin Mine TailingsRelated Information