Service Phone:

+8619870423316

Service Phone:

+8619870423316

Service Phone:+8619870423316

Service Phone:+8619870423316

current location: home > News and information

24-hour phone/WhatsApp:+8619870423316

24-hour phone/WhatsApp:+8619870423316

Slag refers to the solid waste formed by cooling and solidification of impure substances generated during metallurgical processes such as steelmaking and ironmaking. The iron content of slag is high, and if not treated, it will cause serious pollution to the environment. Therefore, the slag sorting production line has emerged as the times require.

1. Working principle of slag sorting production line

1. Working principle of slag sorting production line

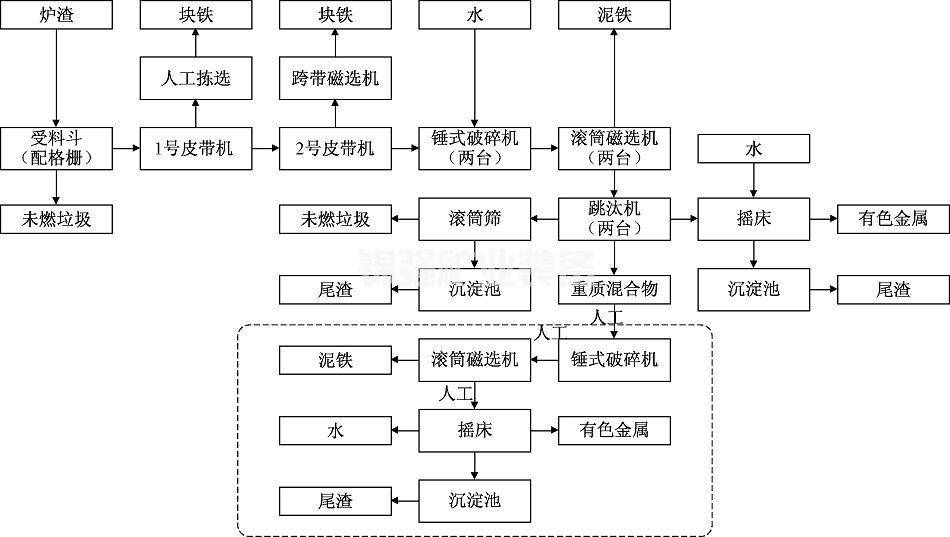

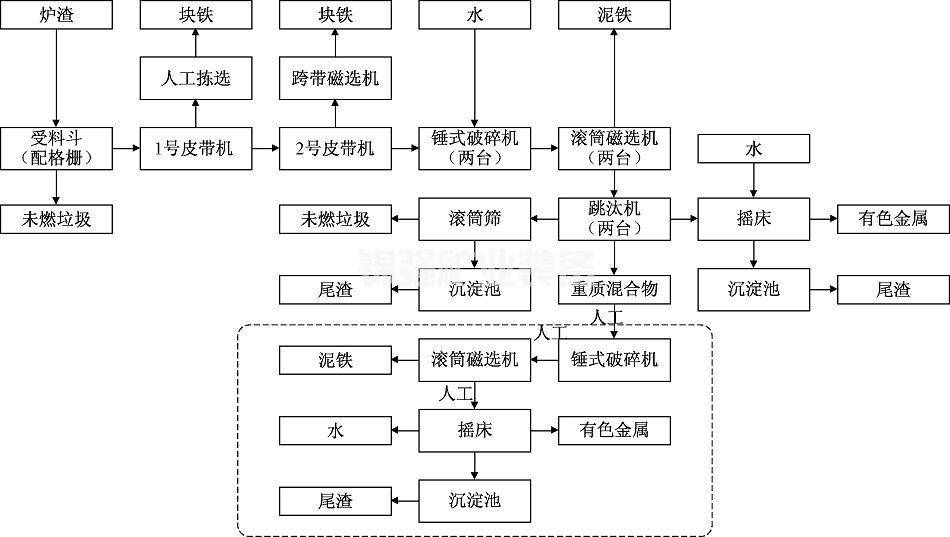

The slag sorting production line mainly uses equipment such as vibrating screens, magnetic separators, and airflow separators to screen, magnetic, and airflow sort the slag, separating valuable metal materials such as iron and steel from the slag.

2、 Operation steps of slag sorting production line

1. Slag feeding: The slag is fed through a conveyor belt to a vibrating screen for preliminary screening.

2. Preliminary screening: The vibrating screen divides the slag into two parts: large particles and small particles. The large particle slag is directly sent to the magnetic separator for magnetic separation, while the small particle slag enters the airflow separator for airflow separation.

3. Magnetic separation: The magnetic separator separates valuable metal materials such as iron and steel from the slag through magnetic force, and the separated materials are sent to the next step of processing through conveyor belts.

4. Air flow sorting: The air flow sorting machine separates the light impurities in the slag through the action of the air flow, and the separated materials are sent to the next step of processing through a conveyor belt.

5. Fine screening: Fine screening further screens the slag to separate the remaining light impurities, and the separated materials are sent to the next step of treatment through conveyor belts.

6. Final sorting: The final sorting separates valuable metal materials and residual light impurities from the slag. The valuable metal materials are sent to the next step for treatment through conveyor belts, and the remaining light impurities are sent to the waste slag bin.

3、 Advantages of slag sorting production line

1. Resource saving: The slag sorting production line can separate valuable metal materials from the slag, saving resources.

2. Environmental protection and energy conservation: The slag sorting production line can separate valuable metal materials such as iron and steel from the slag, reducing environmental pollution.

3. Improving efficiency: The slag sorting production line adopts an automated control system, which can improve production efficiency and reduce manual operations.

4、 Application fields of slag sorting production line

The slag sorting production line is mainly used in industries such as metallurgy, steel, building materials, etc. It can separate valuable metal materials from the slag, save resources, and reduce environmental pollution.

In short, the slag sorting production line is an efficient, environmentally friendly, and energy-saving equipment for treating slag, with broad application prospects.

Slag sorting production line

Slag sorting production lineRelated Information